|

Gas compressor package

Gas Turbine Fuel Booster

Compressors are used in gas turbine fuel boosting applications for compressing natural gas from low to higher pressures levels. The gas is compressed to constant discharge pressures, such as those required by natural gas fired combustion turbine-generators for generating electricity. The fuel gas compressors ensure continuous supply of fuel gas at specified discharge pressures to the turbine-generators. |

|

OIL INJECTED SCREW COMPRESSORS

Description

Screw compressor use two meshed rotating positive-displacement helical screws (see picture below), a female and a male screw. The female having concave inlets and the male convex helical inlets.

|

|

|

As the screws rotate, gas is drawn into the inlet port and fills up the space between the screws. This is the admission phase. The key phase is compression. This starts when the end of a male thread blocks the end of a female thread. The volume available between the compressor body and these two threads is then progressively decreased during rotation. When this volume merges into the delivery outlet of the compressor, the third phase takes place. This is called the Exhaust phase.

Throughout this process, there is no contact between the screws. This means no wear, total reliability, and a non-pulsating gas delivery. |

|

Capacity control

Variable compressor displacement (slide control system) is a well proven technology of flow control conditions, developed especially for applications where a variable, non-pulsating flow control is required.

This control technique consists of a slide valve positioned in the casing. During transient conditions, the slide valve opens or closes to maintain a constant output pressure, bypassing a portion of the compressed gas back to suction.

The slide is actuated hydraulically and by means of the compressor differential pressure applied to the slide. The slide position is controlled by an electronic sensor.

The slide capacity control range is between 10-100%. This provides the capability to start the compressor at no load.

|

|

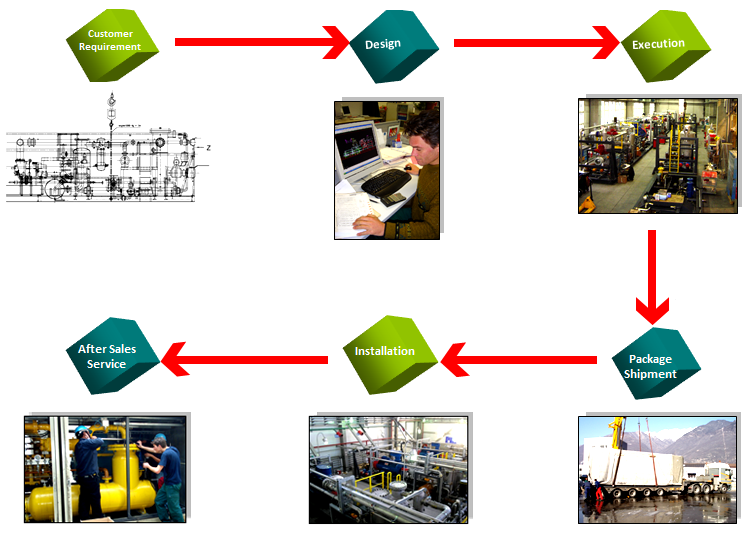

Chain Management

|

|